ABOUT THIS YACHT

2009 / 2023 Refit (Full Refit) VICEM CLASSIC 71

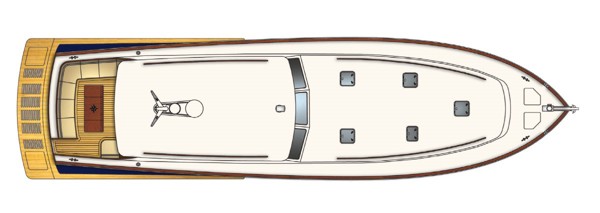

Vicem 71 Classic model was manufactured from carefully selected mahogany wood, far beyond the mass production standards in which first she embraced the seas in 2009.

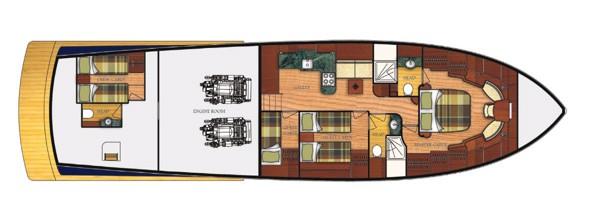

With her 2 X 1100hp Man engines capable of max speed at 30 knots without disturbing the comfort of her guests, this Giant Lobster with 3 staterooms, 2 head-showers and 2 cabins for the crew and countless facilities, she crossed many seas with her first owner until 2012 and in 2012 she met her 2nd owner.

Comfort and practicality have always been her priority and she has always been ready to serve with high standards, the owner's high priorities and being a pro-yachtsman made him her to take her to the next level and with Acar Yacht-Istanbul with 4 generations of shipyard perfectionist experience, this beauty has been transformed; After 6 months of intensive work with 2 new generators, PLC system, full camera system + FLir night vision, new water maker; mechanical, electrical and electronic new infrastructure, interior design, teaks, hull reinforcements and numerous operations, Lamara 1 has undergone the highest level Full Refit Process in 2023 and has been made ready for navigation in the world seas by maintaining its Classic-Modern line:

Highlights of the operations carried out:

-The exterior facade was cleaned of old paint and coating.

-After removing the old coating, was covered with 8mm thick Okouma water contra.

-Insulation was ensured by coating with epoxy fiber after the contra coating.

-Jotun brand fine epoxy putty was applied and all burgundy was sanded with 3-meter gauge sandpaper.

-After primer paint, top coat paint was applied.

-The varnish on all wooden surfaces was cleaned with sandpaper and 15 coats of varnish were applied again.

-The old teak coating was removed and the entire deck was covered with epoxy fiber and finally insulated with peel ply.

-All decks and cockpit areas were covered with first class Burmese teak.

-The platform was dismantled and designed in a new form, cleaned with sandpaper, and then brought to its first day appearance with teak oil.

-Hamann system maintenance done.

-All necessary parts of the engines were dismantled and rectified.

-Air conditioning engines were dismantled and maintained, control panels were replaced with digital ones.

-New water maker was installed.

-All hydraulic hoses replaced with new

-The design of the small cabin was changed and bunk beds were added.

-Galley design changed.

-Refrigerator and electrical panels were replaced.

-New galley countertops were manufactured.

-Saloon curtains and sofa upholstery were replaced. Poufs that can be combined into a bed manufactured.

-All cabin beds were specially re-manufactured.

-Adjustable sun beds and awning added.

-Cockpit upholstery and furniture replaced with new